Professional Mobile Trailer-Mounted Soda Blasting System

The ultimate machine for professional soda blasters. Wide range of applications with all components necessary for operation.

Trailer, Compressor, and Blast Equipment are Made in the USA

Low-profile deck with ample space for storage

120-150 minutes continuous blast time per fill

Lifetime warranty on blast pot

- Sku: SWBB100MBLN

Description

Introducing the BB100MBLN Professional System, an innovative and rugged soda blasting solution engineered for unparalleled efficiency and precision in industrial applications. This proprietary system is purpose-built for soda blasting, setting a new standard in performance. Powered by a robust high-pressure air compressor, this trailer-mounted unit ensures exceptional mobility and power on job sites. Equipped with advanced cooling and moisture elimination technology, paired with our patented self-cleaning venturi blasting pot, the BB100 professional system ensures seamless operation and precise blasting accuracy. Expand your operational capacity with the capability to accommodate multiple blasting pots for enhanced productivity. This system is an all-in-one system designed for the active soda blaster and will supply enough efficiency & power for 99% of applications.

- ACH / e-Check - We can provide you details to initiate an ACH from your end or we can also provide you with an option to submit your banking information to us for an ACH pull.

- Wire / Bank Transfer - We can provide you with banking details so you can wire funds directly.

- Credit Cards - Available for certain transactions under $15,000 in total.

- Physical Check / Money Order - You are welcome to mail a check or money order to us for payment.

- ☝ We Offer Financing - If you are interested in financing your purchase, contact us to let our team help you find the best option.

ACH, e-Check, Wire options are preferred for any order over $2500. Further details on these options will be available during checkout.

The size of this item limits our delivery options. Many of our customers choose to pick up the trailer mounted system when its ready since we also offer hands-on training during pickup as well. However, we do have the option to ship it via freight if necessary.

If you are having trouble viewing, view a larger shipping map here

| Zone 1 | Free Delivery on Equipment, Parts, and Blast Media | |

| Zone 2 | Free Delivery on Equipment & Parts / Subsidized Rates on Blast Media | |

| Zone 3 | Free Delivery on Equipment & Parts / Subsidized Rates on Blast Media | |

| Zone 4 | AK, HI, Everywhere Else- Subsidized Rates. Please Call or Email to Order |

Due to the wide variety of sizes and weights of our items we offer a customized set of options for delivery. The various delivery options, when available, based on product size and weight are:

- Customer Pick Up, if product in stock at our Locations

- Small Parcel Delivery via UPS, FedEx, or Similar

- Freight Delivery via various LTL and FTL partners

Reference the map above for our current shipping promotions. We offer free or promotional delivery rates for all orders in the contiguous USA. Don't worry if you live elsewhere, we still subsidize freight delivery no matter where you are, we will offer below cost delivery for any other location in the US or beyond!

Freight Delivery Information

For orders of sufficient size and weight to require freight delivery, free delivery only applies to commercial addresses with a fork lift or loading dock. Additional charges apply for residential and/or lift gate services. Note, the table below does not apply to orders which are sent via small parcel with UPS, FedEx, or similar.

Commercial addresses are designated by our freight carrier partners as commercial sites. Usually, these addresses are zoned for business purposes, such as warehouses, storefronts, and offices.

| Freight Method Pricing | Zone 1 | Zone 2 | Zone 3 | Zone 4 |

| Commercial Address - Equipment and Parts | Free | Free | Free | Call / Email |

| Commercial Address - Blast Media | Free | $139 | $349 | Call / Email |

| Commercial Address w/ Lift Gate - Equipment and Parts | $100 | $100 | $100 | Call / Email |

| Commercial Address w/ Lift Gate - Blast Media | $100 | $239 | $449 | Call / Email |

| Residential Address - Equipment and Parts | $100 | $100 | $100 | Call / Email |

| Residential Address - Blast Media | $100 | $239 | $449 | Call / Email |

| Residential Address w/ Lift Gate - Equipment and Parts | $200 | $200 | $200 | Call / Email |

| Residential Address w/ Lift Gate - Blast Media | $200 | $339 | $549 | Call / Email |

Commercial Address: This option is for commercial addresses with tractor-trailer access and a loading dock suitable for pallet jack or forklift unloading.

Commercial Address with Liftgate Service: For commercial addresses without a loading dock or fork lift, liftgate service is available for an extra fee. Make sure to select this option during checkout.

Residential Address: Proceed with caution when choosing this option for residential addresses, as most lack suitable unloading conditions. You'll need to handle unloading on your own, as drivers usually can't assist.

Residential Address with Liftgate Service: Recommended for residential deliveries, this option includes liftgate service for safe unloading. There's an additional fee, so remember to choose it during checkout.

Professional Mobile Trailer-Mounted Soda Blasting System

A full mobile soda blasting powerhouse. Enjoy the efficiency and convenience of using the only true soda blaster.

Our USA-manufactured soda blast system caters to businesses large and small with unmatched efficiency. Whether it's industrial cleaning, fire restoration, or engine remanufacturing, our Soda Works equipment delivers unparalleled reparability, enhanced uptime, minimal media waste, and an extraordinary production capacity. There's no other machine utilizing soda media that can match its performance.

We have designed our own patented, custom designed trailer mounted system that will give you the very best soda blasting results, period. There is no other system out there marketing itself as a "Soda Blaster" that can come close to the performance of the BB100MB system. Designed from the bottom up for soda blasting only, our system will complete more trouble-free work in less time using less soda.

Our complete Soda Blasting system is built around a Sullivan/Palatek High Pressure air compressor. This compressor is driven by a Kohler diesel and can output 210 CFM at 150 psi. The compressor is trailer mounted so you can simply hitch it up and haul it to your job site.

The air from the compressor is then run through two mounted air coolers. Cooling the air is a preliminary step to removing the moisture. If there is any moisture in the air you use to soda blast, the soda will clump and the blaster will jam. After the air is cooled it is run through our proprietary moisture separator. When it has passed through this stage the air is ready for the soda blasting pot. But before we send the air to the pot we tap into the line with a air supply valve that many of our customers use to feed respirators or other equipment.

The cooled, dried air then is delivered to one of our BB100 (buster blaster) soda blasting pots. It operates using our patented, self-cleaning venturi that requires little, if any, maintenance. The patented venturi valve, combined with our optimized metering system, virtually eliminates clogged lines and delivers a precise, even flow of the blasting medium.

The BB100 Mobile Unit is the only soda blasting system designed from the ground up just for soda blasting. From air delivery to soda delivery, there is no other system that performs better. There is no other system that is as maintenance and trouble free. There is no other system that uses the blasting medium as efficiently and effectively as the Buster Blaster 100 system.

Will work best for up to #5 (5/16") nozzle sizes.

Ideal for 99% of common soda blasting applications.

- Sullivan-Palatek Mobile Air Compressor (210 CFM @ 150psi)

- Soda Works Patented BB100 Blast Pot (100lbs Media Capacity)

- Soda Works Centrifugal Moisture Separator—375 CFM

- Soda Works Twin Air Cooler—375 CFM Capacity, 12V Switched & Fused Fans

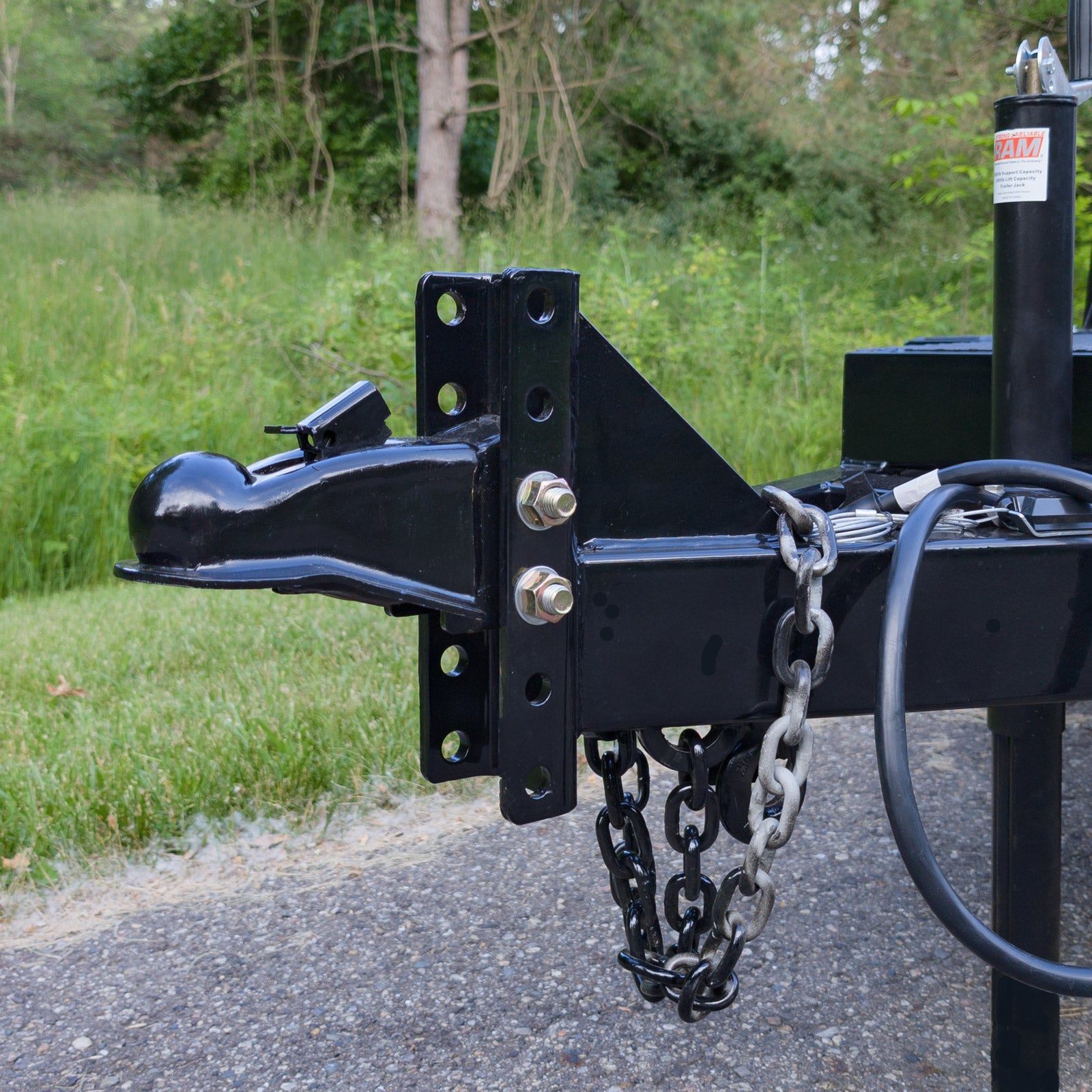

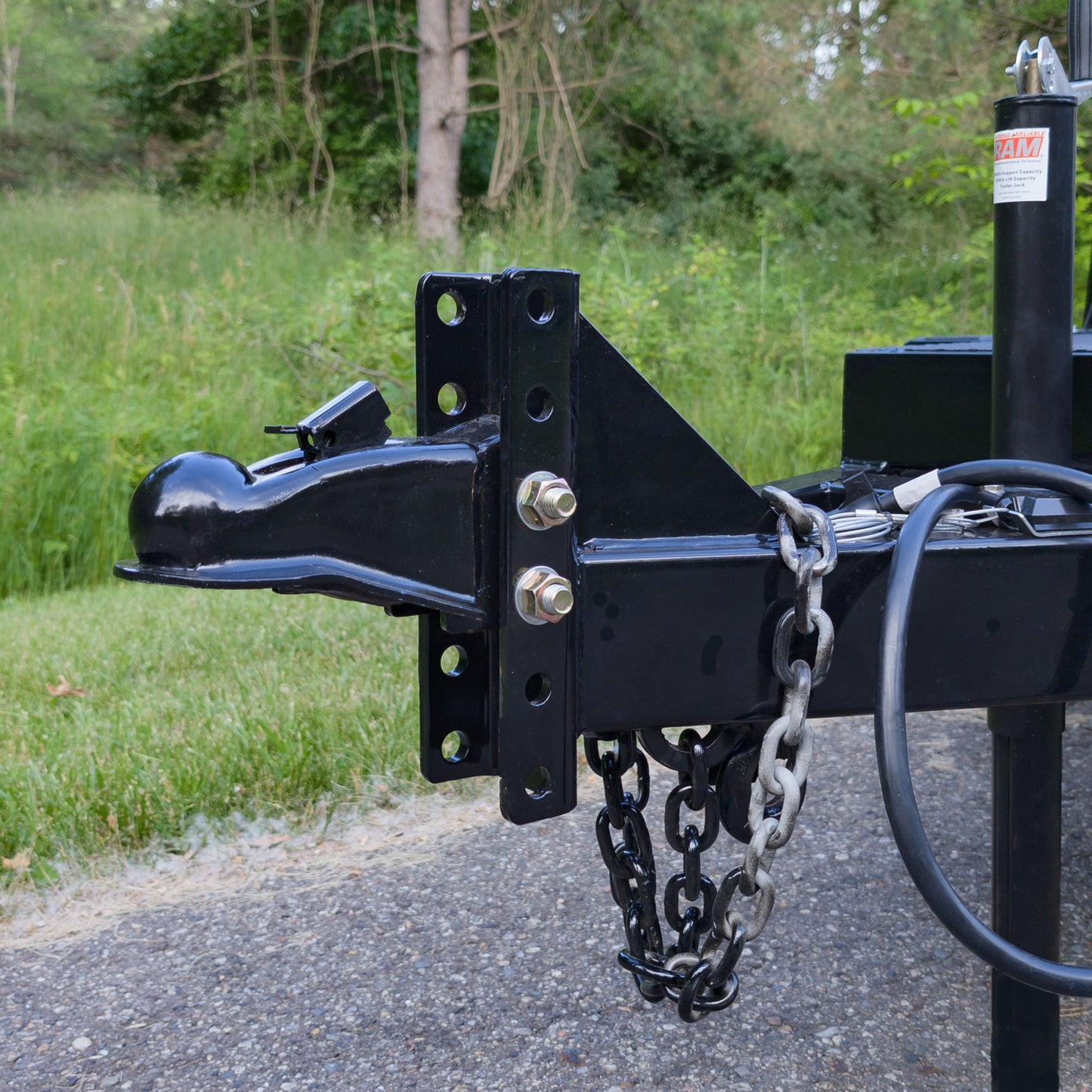

- Trailer mounted with electric brakes for maximum portability and minimal setup time

- Stainless Steel Fittings/Piping

- Electric Trigger Actuated Rotary Valve

- Tethered Trigger Lock

- 100’ 3/4” ID Blast Hose

- 105’ HD Trigger Wire with Rebuildable Trigger

- 1/4 (#4) & 5/16 (#5) Dry Blasting Nozzles

- Aluminum Fill Funnel with Screen

- 2 Gated Auxiliary Air Ports

- Easy Underside Access for Compressor Maintenance

- Comprehensive training provided on-site at our locations or remotely over the phone or email

Technical Specifications

- Overall Length: 16' 11” (203”)

- Overall Width: 8' (96")

- Overall Height: 6’ 3" (75”)

- Gross Weight: 3,879 lbs.

- Braking: Hydraulic Surge

- Ball: 2 5/16”

- Tongue Weight: 185lbs

- Lights: DOT Package

BB100MBLN Download Printable/Shareable Flyer

D210PHKR Portable Compressor Printable/Sharable Flyer

Automotive

Aerospace

Marine

Food Processing

Fire/Smoke Restoration

Mold Remediation

Metal Stripping

Graffiti

Concrete Cleaning

Swimming Pools

Food Service

Carbon Fiber

Fiberglass

Asphalt & Tar Removal

Industrial

Brick and Tile

and Many More

How much capacity do you need? It depends upon the size of the nozzle you are using. When you are using a nozzle with a larger opening, you increase the flow of air and soda and have a larger "brush" to blast with.

CFM consumption will vary by blast nozzle and operating PSI of the compressor. You can refer to our CFM consumption guide for details.

Keep in mind the data on this guide does not take into account PSI and CFM loss due to necessary open valves to purge moisture on the air cooler and moisture separator. So, a best practice is to have a compressor that exceeds your requirements.

You will only require Personal Protective Equipment (PPE) and soda blasting media. Everything else required to start soda blasting is included in this kit. We can, of course, help you with the soda blasting media.

Included in the pricing of this kit is comprehensive training. You can do your training in-person at any of our locations. Alternatively, we can provide remote training if travel is not possible.

The Total Package

Simple, rugged quality that shows

Made in the USA from components that are made to last. Our design is simple, designed to be field repairable. Everything you need to get the job done efficiently without the frills that are prone to downtime and time consuming repairs.

We utilize stainless steel plumbing throughout along with all surfaces being powdercoated or stainless.

Complete Mobile Soda Blasting System

Less Setup Time, Less Dust, Less Cost and more Productive

Our mobile system is ready to go any time. Hook up to the trailer and you are on your way. Cut your setup time in half compared to renting or towing a separate compressor.

Our patented system allows the operator to precisely tune the flow. Get more done, waste less media, make less dust, and enjoy the cost savings.

From heavy-duty coatings to light furniture stains, our system ensures top-notch effectiveness with less soda use.

How Does Our Soda Blasting System Work?

Just air and soda, right? When it really comes down to it that is all it is. We just do it more efficiently with less dust, less waste, and with more production than anyone else.

The air generated by the compressor is passed to a specially designed dual fan air cooler that will take the other wise hot air exiting the compressor and cool it to ambient or cooler temperatures. Then the air is passed to the moisture separator. Here the cool air spins and pushes the moisture to the walls where it travels out the bottom by way of a valve. The now cool and dry air moves from there into the blast pot where the blasting soda media is introduced. Through a specialized patented metering system, the air and soda move through the system when the trigger is activated by the operator at the nozzle.

Cool The Air

Dual Fan Cooler for Maximum Power

Why do we need cool air? When air cools, it loses its capacity to hold moisture, and the excess water vapor condenses into liquid droplets, which we often see as dew or, indoors, as condensation on windows.

Soda flows best when its free of moisture. So, our specially engineered dual fan cooler paired with our advanced kit ensure up to 375 CFM of air is cooled to the appropriate temperature so our moisture separator can do its job to eliminate clog-causing moisture.

Dry Air Is Critical

Centrifugal Steel Moisture Separator

Dry Air Is Critical

Centrifugal Steel Moisture Separator

With our moisture separator, air whirls rapidly, pushing any moisture to the walls and out through the bottom outlet. The result? Dry air that boosts uptime, improves results, and enhances production. It's efficiency at its best.

All Critical Accessories Are Included

Hoses, Control Lines, Nozzles, oh my!

All Critical Accessories Are Included

Hoses, Control Lines, Nozzles, oh my!

Add some diesel fuel to the compressor and load your soda media into the pot and you are ready to get to work. All critical and common accessories are included in this kit. Need specialty items like wet nozzle, fan nozzle, extra hose or control lines? We can help with that too!

Have Questions or Need Help Identifying the Best Option for You?

Get in touch with our US based team of pro's now! We are ready to help ensure you get what you need to do the job right.

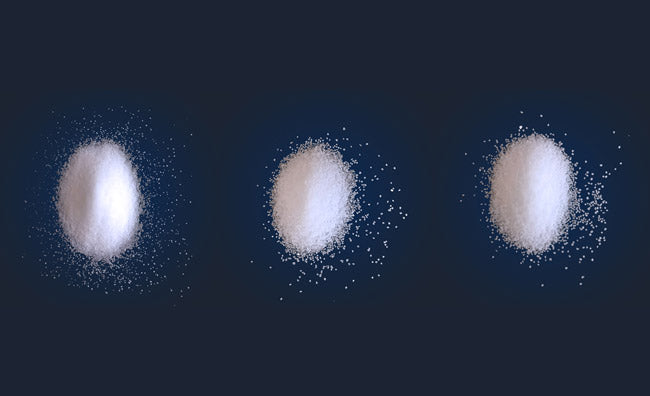

Our Equipment Works Best When Paired With Our Blasting-Formulated Soda Media

Soda Works Equipment + Soda Works Media = Best Results

Our blasting systems perform best when using filler free food grade sodium bicarbonate that is formulated for blasting media. We offer specialty soda media that has been extensively tested to increase production, reduce dust, and maximize efficiently. Available in 3 different particle sizes.